- Natural: caused by the flow of air through the tunnel due to atmospheric conditions or to the piston effect of vehicles travelling through

- Mechanical: a fan-powered ventilation system with a specific function, such as providing fresh air, cooling, removing fumes or controlling smoke or fire

Tunnels with semi-transverse or transverse main ventilation systems for routine use sometimes have a second system for smoke control.

Ventilation systems are found in highway tunnels, which tend to be of more modern construction and are necessary due to the high concentration of contaminants. Rail tunnels may have ventilation systems in the stations or at intermediate fan shafts, but during normal operations rely mainly on the piston effect of trains to remove stagnant air. Some rail tunnels have emergency mechanical ventilation that operates in the event of a fire to control smoke.

It may be beneficial to use joint on-site training to identify and understand the use and control of ventilation systems.

Mechanical tunnel ventilation systems can be categorised into four main types:

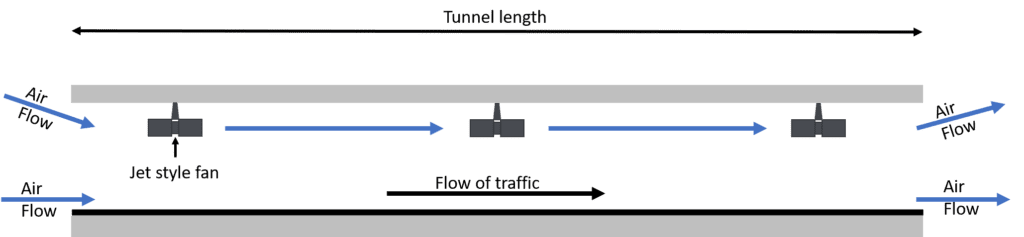

1. Longitudinal ventilation is similar to natural ventilation with the addition of mechanical fans normally located in the tunnel. Fans, often referred to as jet fans, are used inside rectangular-shaped tunnels that do not have the space to facilitate air circulation above the ceiling or below the roadway. Also, shorter circular tunnels may use the longitudinal system since there is less air to replace; therefore, the need for even distribution of air through ductwork is not necessary. Where flow can be reversed, the fans can be used to move air into or, in the event of a fire, out of the tunnel through the tunnel openings.

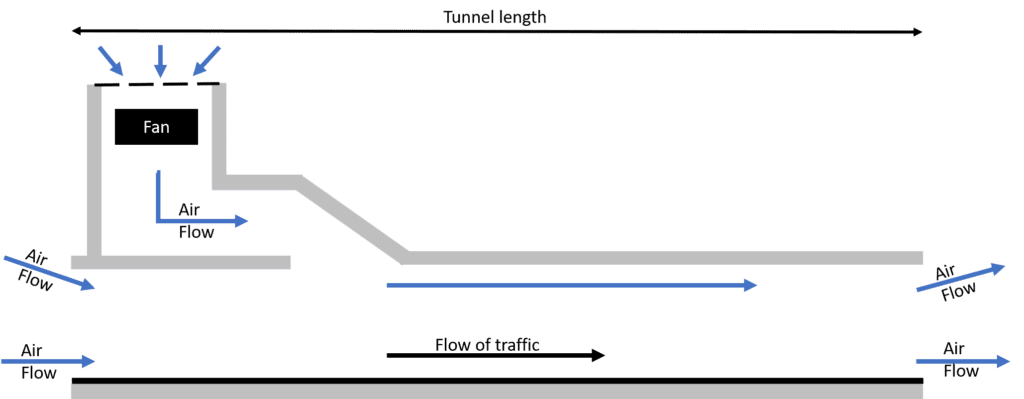

Another less common type of longitudinal ventilation system uses a configuration known as a Saccardo nozzle to provide uni-directional longitudinal ventilation. This is used where headroom in the tunnel is limited, such as in a retrofit for an existing unventilated tunnel.

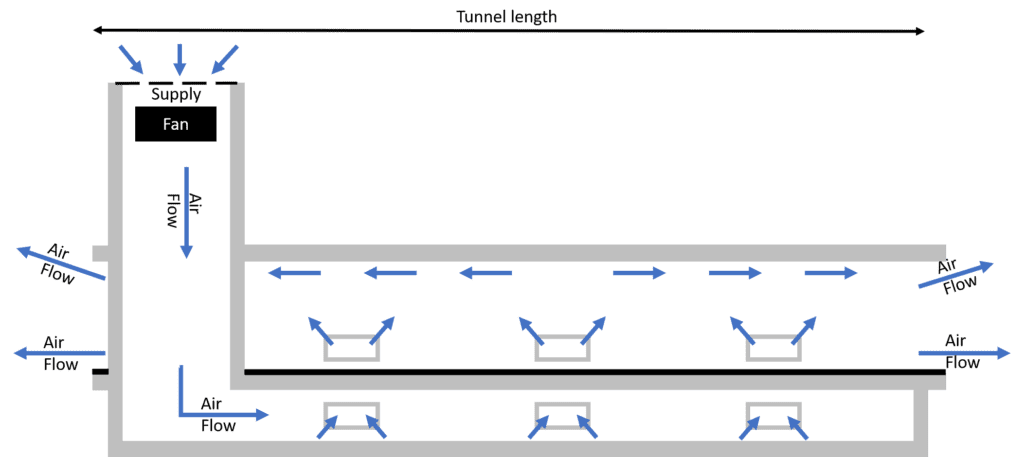

2. Semi-transverse ventilation also makes use of mechanical fans for movement of air. Fresh air is normally introduced transversely throughout the tunnel length with contaminated air being exhausted longitudinally through the portals. An adjoining space known as a plenum is used to facilitate air supply, which is incorporated above or below the tunnel with ducts and air distribution units that allow for even distribution of air throughout the tunnel.

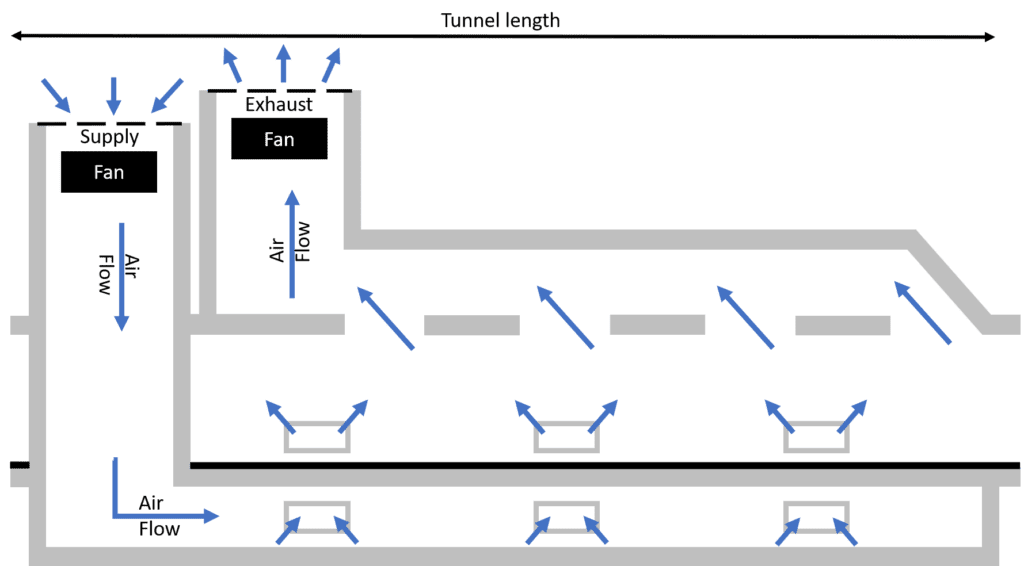

3. Transverse ventilation again uses mechanical fans for movement of air. With a transverse ventilation system, fresh air is normally delivered transversely along one side of the tunnel with corresponding extraction points for contaminated air along the other. Airflow is transversely across the tunnel cross-section. Both fresh air supply and exhaust air removal is by means of plenums running longitudinally along the tunnel. These can be formed in the space below the road surface or above a false ceiling to the roadway. The ventilation system makes use of mechanical fans, but these are located in ventilation facilities external the tunnel.

4. Single point extraction can be used in conjunction with semi- and full-transverse ventilation systems to increase the airflow potential in the event of a fire in the tunnel. The system works by allowing the opening size of selected exhaust vents to increase during an emergency. This can be done by mechanically opening louvres or by constructing portions of the ceiling out of material that disintegrates during a fire, thereby providing a larger opening. Both of these methods are rather costly and therefore seldom used. Newer tunnels achieve equal results simply by providing larger extraction ports at given intervals that are connected to the fans through the ductwork.

For control measures relating to fires in tunnels refer to:

- Fires in buildings – Appropriate intervention: Fire in tunnel

- Fires in buildings – Ventilation systems

Whichever system is installed, contact with local tunnel management will establish the capability of the ventilation system to control smoke or fumes in an emergency. This will allow the incident commander to determine whether it will provide adequate protection for those evacuating under the guidance of the tunnel manager, and for responders being committed.

If mechanical ventilation is uni-directional or controllable, this will allow pre-prepared plans to define a default air flow direction, this creates a preferred entry point at the inlet end of the tunnel. Plans should then have responders committed in this direction.

Incident commanders should not attempt to control the ventilation system themselves; they should instead instruct the people who normally control it, as to what is required from the system.